Are you a serial A/C compressor killer?

These days customers are a much savvier breed. The internet provides them with more information and this has led to a growing need to understand why a certain part may have failed on their car and, in some

instances, can allow them to bring knowledge and information to the workshop upon booking in for a repair.

The smart workshops will work with their customers and agree a suitable plan of action, especially if it’s a job that they’ve not come across before. Working with your customers can create a partnership and relationship for the future, so it’s essential that you can competently undertake servicing and repairs

of key systems, such as the A/C circuit.

A/C system and compressor failures

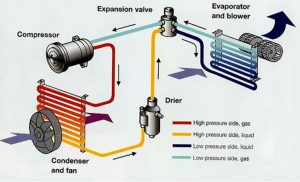

A/C compressor (and system) failure can be the result of several factors, including: system leaks generating oil starvation; poor cooling system temperature control; worn drive belt tension set-up; and moisture and acid build-up from the system remaining empty and creating internal corrosion which, in turn, creates refrigerant and lubrication restriction and blockage. The system must contain the correct type and amount of PAG OEM oil, holding the appropriate refrigerant charge weight and remaining in a leak free condition. The system cooling and condenser fans must operate as designed by the VM, but unfortunately these components are largely ignored until a compressor failure occurs.

Why do syste ms leak?

ms leak?

Condenser and pipework leaks can be generated from: internal moisture and acid build-up from the system remaining empty and creating internal corrosion; external stone chips; and road salt and chemicals attacking the aluminium surface. On occasions where you’re presented with an A/C related issue, careful diagnostic consideration should be applied so as to further investigate why components such as condensers have failed.

Although simply removing the failed components (taking the view that they’ve failed or worn out), and refitting a new part before recharging the system, may well ‘fix’ the failure in the short term, in the long term it will not do your company’s reputation any good because of the increased risk of a ‘come-back’. The costs of such remedial work could then eat into your profits and send your customer into the open arms of one of your competitors.

To further support its customers, CompressorTech provides full fitting instructions with its products as well as reasons as to why the A/C compressor has failed. Additionally it has introduced a 30 point ‘step-by-step workshop inspection pad for its customer so they can carry out a thorough diagnostic inspection before any repair work is actioned. Carrying out A/C diagnostics and repairs can be a very profitable and efficient use of workshop time, but for the customer and technician to achieve ultimate satisfaction

from A/C repairs, it’s vital that the process is completed in the correct way.