The latest Technical Guide from Apec, takes a look at a recent case study which addresses the problem of premature wearing of the outer pad.

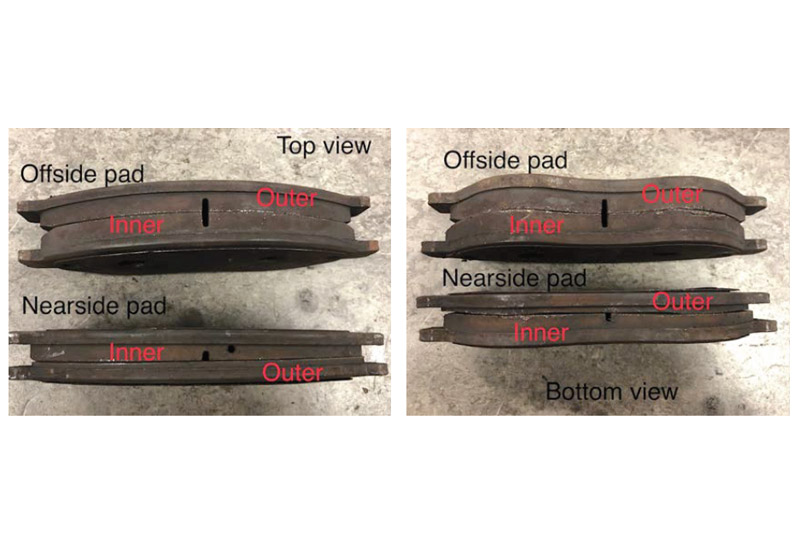

This issue had spanned over a few months. It had started with the owner of the vehicle purchasing the vehicle and requesting for the brakes to be replaced. A few months after the brakes were replaced the owner reported of squealing noises at low speeds as well as a burning smell. Upon removing the front discs and pads, they discovered that the NSF outer (or finger side pad) had worn down considerably more than the inner pad.

Suspecting that this is a caliper issue, they replaced the caliper together with a new set of discs and pads. However, after this replacement the owner still complained of a squealing noise and an abnormal braking sensation. The garage, suspecting that the issue was with hydraulics further up the brake system, chose to replace the hose in case of a blockage. Following best practice, the garage ensured that the sliders were recleaned and re-lubricated to ensure free movement of the braking components. Unfortunately this still did not resolve the issue and, suspecting a faulty caliper, decided to replace the caliper twice more without success. Apec’s Techmate team were contacted to provide some assistance to resolve the issue.

To ensure the correct diagnosis, Techmate apply their knowledge of brake operation. Techmate will always follow a process of diagnosis and elimination by using precision measuring tools. After a test drive to confirm that the symptoms were present, the vehicle was stripped for the parts to be inspected and measured. Contrary to the garage’s diagnosis that the caliper piston is seized, Techmate suspected that as the outer pad (finger side) was wearing prematurely, the actual issue could be due to the outer pad not returning after the brake pedal had been depressed. As a result of this the outer pad would have been left in contact with the brake disc causing the brake pad to wear prematurely.

However, to ensure that there is no issue with residual hydraulic pressure causing the caliper to bind, a hydraulic pressure gauge was attached to the caliper to confirm this. With the gauge attached, without any pressure on the brake pedal, no pressure will be recorded on the gauge. To ensure that the caliper pistons are moving freely, hydraulic pressure was blocked to the caliper by clamping the brake hose followed by pushing the pistons back into the caliper with the bleed nipple undone. The brake fluid expelled can then be examined to ensure its condition and eliminate it from being contaminated to cause the piston to seize. The caliper pistons retracted easily indicating that the pistons will move freely without any obstruction. The brake fluid expelled wasn’t contaminated and this proves that the brake fluid wasn’t causing the pistons to seize. With the caliper removed, the brake pads were moving freely in the carrier and there was enough lubrication to assist with movement of the pads. The sliders were moving and had abundant lubrication to assist with movement.

As all components have been proven to move freely when disconnected from each other, Techmate suspected the possibility of a component that could be misaligned. Due to this misalignment, it would prevent the outer pad from returning. To confirm that the brake disc is in alignment, a run out measurement was taken to eliminate the brake disc as a source of misalignment. The maximum amount of tolerance for brake disc runout is 0.08mm. The runout reading was 0.04mm which eliminates the brake disc.

The other source of misalignment is the brake carrier, should this be misaligned, would be positioned in an angle that would prevent the outer brake pad from returning. To confirm this, a feeler gauge was used to measure the gap between the disc and the carrier and compared the differences between the nearside and offside. By measuring, this confirms that there is a definite difference in measurement between the two. With the caliper bolted on to further confirm the misalignment, the nearside caliper kicks out slightly indicating a misalignment rather than moving laterally when the brakes are applied.

The carrier was replaced curing this issue and Techmate was delighted to have assisted to resolve the issue. If you ever have any questions, please feel free to contact our technical helpline on 01174 288100. Apec Braking is proud to provide you with technical information to support the quality of its products and to uphold its “Full Spec. Full Stop.” promise to customers.