According to studies by Nissens, 43% of the current car parc is fitted with a turbo – a figure that is expected to grow by 30% before 2019. And with an increased focus on the environment, as well as greater attention to engine downsizing and fuel economy, the intercooler is being pushed to the limit like never before.

Engines are becoming more and more efficient, with every part of the engine being optimised and tested. While the use of turbocharged engines generally provides a number of benefits, such as increased engine power and efficiency, lower fuel consumption, lower engine emission values and less thermal stress on the engine, previously infrequent engine issues have become more and more regular, and new ones will occur, as the systems are being pushed further.

Since its introduction more than 30 years ago, the turbo has shrunk to half its original size, but has doubled in RPM and pressure, while the temperature has been increasing to gain the desired effect. All of this increases the pressure on the intercooler, as the diffe rence between the input and output air temperature is increased. Eventually, this will cause an increase in intercooler failures.

rence between the input and output air temperature is increased. Eventually, this will cause an increase in intercooler failures.

PROBLEM

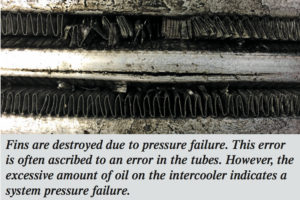

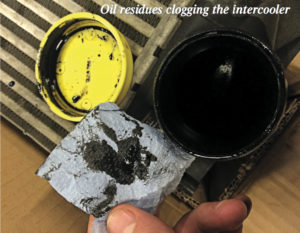

While product failures caused by stones and particles from the road, causing external damage and leakage to the intercooler, are currently the main reason for issues, two other problems are increasing in appearance with the spread of turbos:

■ Clogged intercoolers

■ Leaking intercoolers due to abnormally high system pressure

WHAT ARE THE ISSUES?

It is critical that mechanics are aware of the issues related to the intercooler, and that they always follow the installation guides. Defective or leaking intercoolers will often display a range of different issues, three in particular being more common. The Nissens Product Manager, Steffen B. Jensen, elaborates:

“What often enables a mechanic to identify a defective or leaking intercooler is a noticeable drop in the engine power, increased fuel consumption or unnatural smoke from the exhaust system. As the pressure in the turbo-charged system is not right, the fuel/air mixture will have an insufficient amount of oxygen, causing the engine power to decrease. This loss of oxygen in the system will affect the combustion process, causing the vehicle to increase its fuel consumption. As a result of this effect, unnatural smoke will develop in the exhaust syste m, as the increased amount of fuel in the system cannot be combusted and emitted properly from the exhaust system. To compensate for this effect, even more pressure is put on the turbo, which, in the worst cases, can cause it to break down.”

m, as the increased amount of fuel in the system cannot be combusted and emitted properly from the exhaust system. To compensate for this effect, even more pressure is put on the turbo, which, in the worst cases, can cause it to break down.”

SOLUTION

If a mechanic installs a new turbocharger, without investigating the intercooler first, the system will run a high-pressure sequence where oil and particles that have accumulated in the intercooler are at risk of being blown into the combustion chamber. If this debris enters the combustion chamber, then there is a great risk of damage to the engine.

For that reason, Nissens argues that an intercooler should always be replaced after a turbo has failed, in order to ensure that the intercooler is free from any debris, such as oil, metal or other particles. When a new turbo has been installed, all system components must be thoroughly examined to ensure that they are not blocked by oil or metal debris.

Nissens studies suggest that 75% of all new European car models introduced in five years’ time and beyond will be fitted with a turbo, making the knowledge of the intercooler and turbo relationship more relevant than ever before.