GENERAL REPAIR GUIDELINES?

Before proceeding to any repair work on the double clutch, ask your customer some basic questions to pinpoint possible causes of damage. If the car is roadworthy, carry out a test drive together with your customer. The customer should be behind the wheel and pointing out problems occurring during operation.

Ask your customer some targeted questions:

- What exactly does not work?

- What exactly is the customer’s complaint?

- When did the problem first occur?

- Did the problem manifest itself suddenly or gradually?

- When does the problem occur?

- What is the mileage of the car?

- What is the driving profile?

GENERAL VEHICLE INSPECTION

Check the following prior to starting repair:

- Fault codes stored in the control unit (engine, gearbox, clutch, comfort, CAN BUS)

- Battery power

CORRECT HANDLING OF THE DMF AND DOUBLE CLUTCH

The following instructions provide important information on the correct handling of the DMF and double clutch. It should also be noted that any repair/replacement work should be carried out by a competent and correctly trained professional:

- Do not install a DMF and/or double clutch which has been dropped.

- Do not clean the components in a parts washing machine.

- Do not disassemble the components.

WEAR TEST

A wear test can be performed in addition to a general function test of the double clutch. To do so, adhere to the following procedure:

1. Ensure engine is at operating temperature.

2. Test drive car in manual shift mode.

3. When in sixth gear maintain engine speed between 1,000 and 1,500 rpm.

4. Then give full acceleration (caution: do not activate kickdown).

5. Observe tachometer.

6. If speed varies by up to 200 rpm under acceleration, double clutch wear limit has been exceeded.

7. If speed remains constant, double clutch has not yet reached wear limit.

8. Repeat test steps 3-7 while in seventh gear.

VISUAL INSPECTION

As a rule, always check the clutch system environment for leakage and defects before carrying out clutch repair work. Before replacing the clutch merely on suspicion of malfunction, remedy any damage caused by broken off parts or oil leakage due to defective seals or seal rings. Replace clutch if contaminated with oil.

Double clutch, gearbox side Double clutch, engine size

NOISE

To investigate complaints of noise coming from the double clutch environment it is essential to determine during the test drive whether noise is caused by adjacent components, e.g. the exhaust system, heat shields, engine mounts, front-end accessories etc.

To pinpoint the noise source turn off the radio, air conditioning and ventilation systems. You may also use a stethoscope at the garage.

DISENGAGEMENT PROBLEMS AND CLUTCH SLIP

Before removing the gearbox and clutch, perform a system check using an appropriate diagnostic tester. If no defect can be identified and other causes can definitely be ruled out, disengagement problems and clutch slip may result, among other things, from incorrect end float at clutches K1 and K2. If the problems manifest themselves immediately after the clutch was replaced, the engagement system may have been set incorrectly and the procedure must be repeated.

DIAGNOSIS

The gearbox and clutch electronics (mechatronics) are diagnosable. The system can be read using suitable diagnostic equipment. System adjustments, which are required after every clutch repair, can also be configured this way.

SYMPTOMS

DMF clamp ring

Problem: rattling

Cause: Clamp ring retaining lug broken off

Remedy: Replace DMF

Caution: Broken parts of the clamp ring may have entered the double clutch. Therefore it is highly recommended that the double clutch be replaced as well.

DMF clamp ring

Problem: Rattling

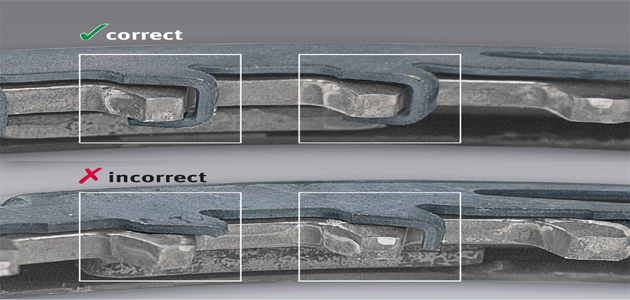

Cause: Clamp ring preload insufficient. There must be no visible distance between clamp ring and drive ring tooth. Force exerted by internal spring must be high enough to push clamp ring back into basic position

Remedy: Replace DMF