Ecobat explains why garages need to be clued up on changes in the battery market.

According to figures released by Ecobat’s (EBT) long term battery partner, VARTA, almost 90% of the cars manufactured this year will feature start-stop technology – and by 2020, so will more than 30% of all the vehicles entering the independent workshop. These vehicles use batteries specifically designed for these systems. Without the correct battery, the start-stop system will malfunction, and the battery could potentially fail.

EBT therefore asserts that it is crucial for workshops to ensure that their preferred motor factor supplies them an appropriate replacement and that technicians follow the correct procedure during its installation. This is why it is wise to begin by being specific about the vehicle when ordering the replacement and don’t assume the battery already fitted is correct, or rely on past experience and ask for a traditional SLI (starter, lights and ignition) battery, because it ‘happens to fit most applications’.

The replacement battery for a start-stop enabled vehicle will be one of two types – absorbent glass mat (AGM) or enhanced flooded battery (EFB), both of which have the necessary capacity to cater for the 4,000 plus different start-stop models currently on the road.

An additional challenge facing the independent is the location of the battery, as only 58% of applications are in the traditional ‘under the bonnet’ location, with 40% in the boot and the remaining 2% – that’s 80 models – situated in the passenger compartment. A further complication is the time required to fit these batteries, which can sometimes be four times longer than for the previous generation. This, however, should be looked upon as a benefit, as the unprofitable ‘free-fitting’ sales spin will have to become a thing of the past, as workshops sensibly charge for the time needed to fit these new batteries correctly.

Whereas the SLI battery in a traditional system undergoes a large discharge of its power to start the vehicle, and is then constantly being charged via the alternator while the engine is running, the AGM/EFB battery is continuously monitored by the vehicle’s battery management system (BMS) and is only fed a charge once its state of charge has dropped to a predetermined level.

Otherwise, all of the vehicle’s electrical systems are powered by the battery to avoid using the engine to power the alternator unnecessarily, thereby reducing both the vehicle’s fuel consumption and exhaust emissions.

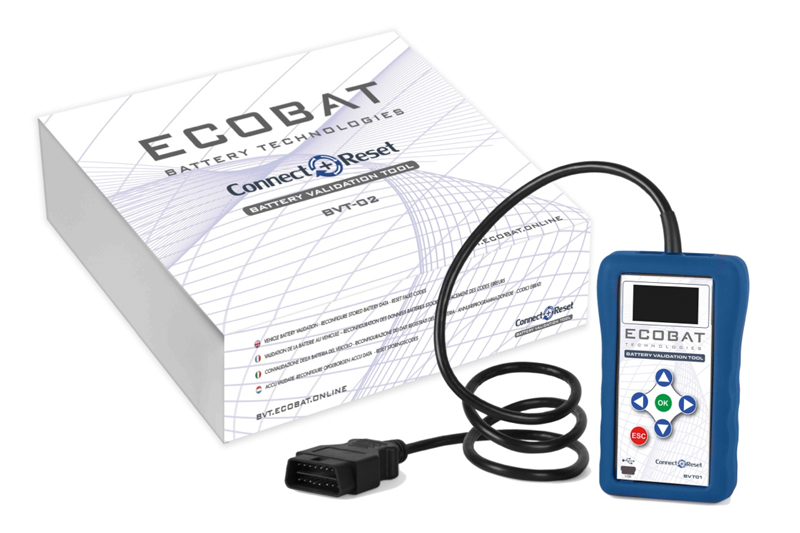

Although in some cases the BMS can operate the charging curve for a new battery based on the battery fitment options stored within and can, over time, ‘learn’ what battery has been fitted and optimise the operating algorithm accordingly, many do not. This means that with these cases, the battery being installed must be registered or ‘validated’ into the BMS via a diagnostic tool to ensure the battery is charged with the correct algorithm. Otherwise, the vehicle will generate diagnostic fault codes and there is the risk of premature battery failure.

Being aware of and prepared for these issues is vital for the independent workshop, as it will enable them to compete with the franchised dealer in the face of this rapidly changing landscape.