To ensure a quality steering and suspension repair, it’s advisable to replace the entire ball joint where the rubber boot is split, cracked, damaged or missing.

In these instances, there is a high probability that damage to the ball joint may have occurred, indicating the joint is likely to fail, even after the boot cover has been replaced.

Replacing the entire ball joint component can help avoid potential premature failure, which can be both safety-critical and costly. By replacing the boot only, and not the complete ball joint unit, the rubber boot could potentially seal in the damaging substances the joint has been exposed to, resulting in accelerated rust and corrosive damage to the joint.

In addition, the ball joint is designed to operate with a grease lubricant. A defective boot could lead to a loss of this essential lubrication, as it may be washed away with water, dry out or become coated with dirt and other debris.

You should also be aware of ‘universal’ rubber boots and associated cable fitment ties, intended for repair and/or modification of the part. The term universal can sometimes be misleading as there are many variations of boots used in any given range; each rubber boot is specifically designed and manufactured for use with its specific ball joint.

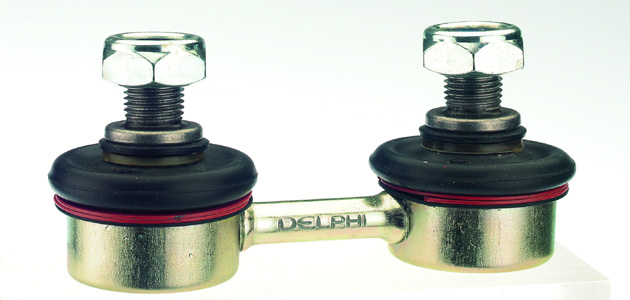

To prevent splitting of the rubber boot in the first place, Delphi’s new dust cover design features an improved Chloroprene Rubber formula that maintains its durability – even in extreme temperatures. This helps protect the internal components and promotes continued free movement of the ball joint.

INSTALLATION TIPS!

■ A press-in ball joint should always be fitted using the correct tool and never a hammer or similar, as this can cause internal component damage.

■ Wheel alignment should always be checked after any new steering component is fitted.

■ Never use an impact gun to fit ball pin nuts or threaded nuts.

■ In relation to steering components with horizontal bushes, securing bolts should only be fully tightened with the wheels fitted and the vehicle on level ground. Failure to do this will cause over-compliance and damage to the bush.