Timing chains usage is becoming more popular in engine manufactures as they offer greater strength and reduced friction. Both of these factors enable engine designers to squeeze more power from smaller capacity engines whilst lower friction coefficients result in more power, less heat and therefore less pollution.

For any engine to operate correctly it must use the correct grade of oil as modern oils are very complex structures that are critical to an engine’s performance and long life.

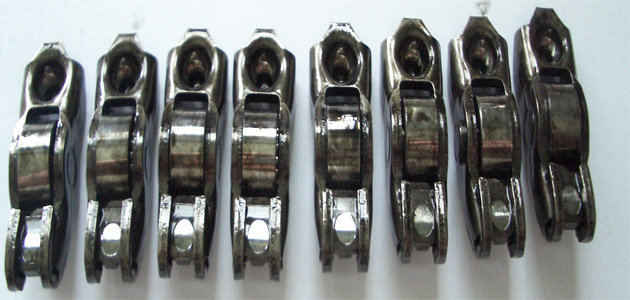

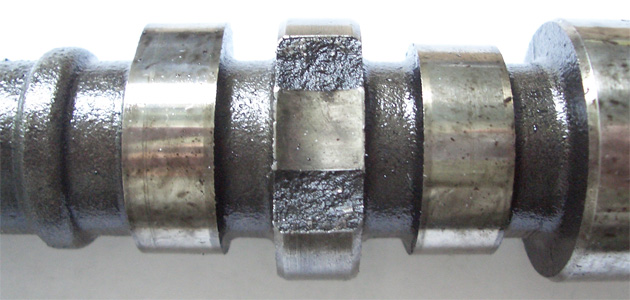

It is essential that the correct oil is used when fitting a timing chain kit; replacing the old oil with a cheaper grade will most certainly cause failure. A timing chain relies on two things to keep working, firstly lubrication is vital to ensure the metal parts do not make contact (at a molecular level), preventing seizure and secondly tension, which in a modern engine is produced 99% of the time by a hydraulic tensioner applying pressure directly or via a tensioner rail onto one or more contact points on the chain. If this pressure is lost or reduced in any way, the chain will start to oscillate, creating fatigue in each metal link and pin of the chain, which will eventually cause the chain to break in one or more places.

It is vital that the tensioner gets the correct volume and oil pressure from the engine’s oil gallery. Without this, the tensioner will be unable to load the chain and failure will occur.

Reasons for tensioner failure can be explained in two ways:

1) If the correct oil isn’t used then the tensioner won’t be able to maintain the correct pressure as the engine RPM increases; high RPM is when the timing chain assembly is at its most vulnerable and consequently most damage can be caused.

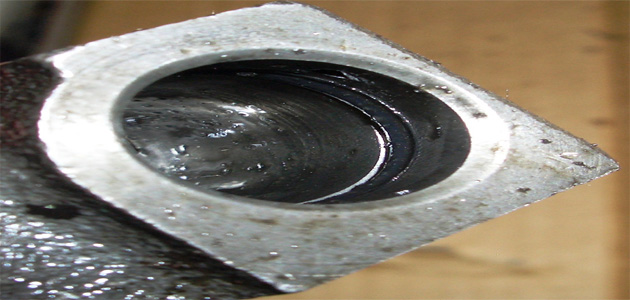

2) All hydraulic tensioners receive their oil feed via an inlet port or valve, the diameters of which range from 1.5mm to 0.50mm. As you can appreciate, if there is contamination in the oil (carbon, metal swarf etc.) the feed holes can become blocked, very easily starving the tensioner, which in turn will fail to load the timing chain.

To prevent chain or tensioner failure FAI recommend that, if possible, the engine lubrication system is flushed just before work is started to remove the old timing chain kit.

This will remove the majority of contaminants that will have built up over the life of the engine. During installation the sump should be removed and inspected/cleaned along with the oil pump and pick up pipe. Using the correct oil and new oil filter will ensure that the timing chain kit will perform at its optimum, as long as recommended servicing and oil changes are adhered to.

Labelling assistance for the user

To help the end user, FAI are rolling out a program of technical information labels specific to each popular timing chain kit offered in the FAI range. The label will give the exact oil specification needed for the kit, including grade (e.g. 0-30W), composition (e.g. synthetic/mineral etc.) and any relevant additional important information such as “low ash” for engines using DPF’s.

THE COMMON USUAL SUSPECTS Common reason for failure – Incorrect oil