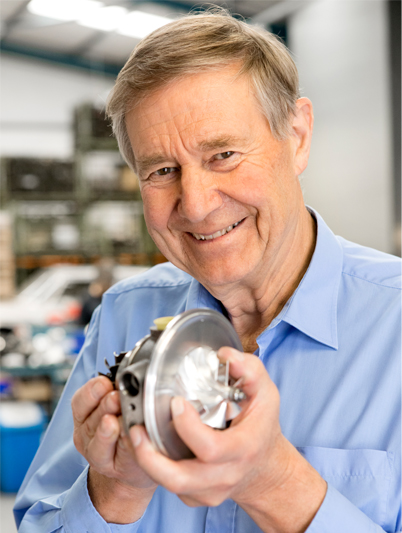

As the turbo market itself has expanded, so has the market for replacement and reconditioned units, but not all of these items are of the best quality and fit for purpose, according to Turbo Technics. Geoff Kershaw, Managing Director, explains his concerns to PMM.

As the turbo market itself has expanded, so has the market for replacement and reconditioned units, but not all of these items are of the best quality and fit for purpose, according to Turbo Technics. Geoff Kershaw, Managing Director, explains his concerns to PMM.

Turbo Technics has been at the forefront of calling for a range of recognisable, industry-approved quality standards to protect garages, as well as provide protection for the motoring public from poorly remanufactured replacement turbochargers. The company has become increasingly concerned about the quality of turbocharger repairs, and close inspection of some of the units at fault has revealed an alarming trend of technicians fitting poor quality replacement turbochargers and components, many of which have been sourced from the internet.

There is an increasing number of reports of garages and workshops facing replacement turbocharger failures, costing these trade outlets money, as well as causing customer relations issues. Evidence of this comes from an independent report by the well-respected Millbrook organisation, the leading vehicle testing facility, which has indicated that replacement turbochargers can be at least 40% down on performance, while also producing higher emissions – a crucial issue for many UK cities – compared to OE-quality remanufactured units.

A turbocharger is often seen as an un- branded product and is often chosen based upon price. However, it is a complex piece of engineering technology that can have a profound effect on vehicle performance and, as such, remanufactured units must be produced to the very highest quality standards, which includes being balanced and calibrated correctly. To this end, Turbo Technics has invested in the production of high quality balance and calibration machines, which are now seen as industry leading equipment.

Buying on price and not quality is prevalent in many industries, but in terms of the automotive servicing and repair industry it really can cause costly problems. Turbo Technics, for instance, has identified an important issue to bear in mind when replacing turbochargers – namely, oil contamination.

Because turbochargers operate at very high speeds and high pressures, the supply of oil is vitally important. To operate at their maximum efficiency, turbochargers require good, clean engine oil. If the oil is contaminated, it can damage bearings or block the flow of oil and cause premature failure, which is not the fault of the turbocharger unit. Turbo Technics runs training sessions for customers at its Northampton headquarters and this is one of the elements covered in the training process.

The company is keen to work with like- minded industry organisations to establish a set of guidelines and standards for the remanufacturing and fitment of engine turbochargers based upon OE quality and operating standards, and encourages technicians to think carefully when choosing a remanufactured turbocharger.