When an ABS light illuminates on the dashboard of a VAG or BMW it can indicate a problem that will start as an intermittent fault and, over time, will become permanent and need repairing.

When diagnosed, the car will likely show a fault code relating to either malfunctioning wheel sensors or a malfunctioning oil pump. This tends to lead to a common conclusion: a fault with a Bosch 5.7 ABS ECU.

This particular component is fitted to a number of cars, including: BMW 5 Series E39, BMW 7 Series E38, BMW X5 E53, BMW Z8 E52, Alpha Romeo, Audi A4, Audi S4, Seat Cordoba, Seat Ibiza and Skoda Fabia.

The ACtronics approach

Prices vary when replacing the unit, but generally it can cost upwards of around £800. In contrast, a remanufactured part – from an expert remanufacturer such as ACtronics – costs considerably less.

Due to the way these particular units are manufactured, however, they are much more difficult to open and therefore require the right level of equipment and expertise to do so. ACtronics uses an eight step process to remanufacture the unit (detailed elsewhere in this article).

The company’s remanufacturing principles are built on its belief that rebuilt electronic components last much longer than those that are simply repaired. As such, the intelligent remanufacturing solutions utilised ensure that all engine parts operate like new, thus enabling ACtronics to guarantee the best service and long term solution possible.

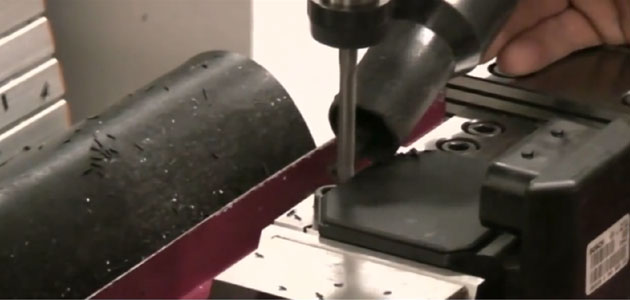

Step 1: The process begins with a precision method for opening the unit. Remove the cap from the old ABS ECU module with a specialist CNC machine, which uses precision cutting to cut through the plastic top.

Step 2: The old silicone gel is removed using a specially developed bath of chemicals.

Step 3: Visually inspect the Bare Die connections and remove all hybrid connections.

Step 4: The aluminium and gold wire connections are made with an automatic ultrasonic bonder.

Step 5: Create new connections for ALL hybrid connections and damaged Bare Die connections.

Step 6: Fill the ABS ECU unit with ‘high specification’ silicone gel.

Step 7: A completely new top is fitted to close and seal the unit securely and a protection cover is used for transport.

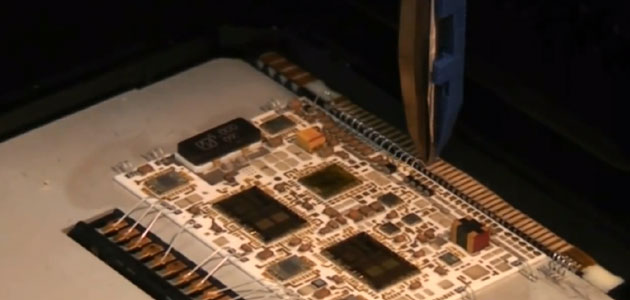

Step 8: The ACtronics Vision 5 machine then fully tests the unit with an automated script program.

Finally… The unit is returned to the garage. The technician can reprogram the unit to reset the fault codes, turning off the ABS light on the customer’s dashboard.

Pay ACtronics a visit at MECHANEX

ACtronics will be present at the Manchester MECHANEX show, where the company’s representatives will be happy to tell you more about its portfolio of remanufactured electronic products and how these can help the independent garage (and their customer) save time and money by avoiding the need for an OE replacement unit. Visit them on stand J14.

Log on to http://www.actronics.eu/en/ to find out more.