PMM visits Dave Jones & Son Quality Motor Service to find out why the business believes apprenticeships are so important for the industry.

Dave and his son Mark’s family- run business, located in New Milton, Hampshire, was founded in 1995, with quality, attention to detail and pride in doing a good job said to be at its heart. With over 50 years’ experience as a mechanic, Dave prides himself on instilling the ideals of quality and honesty in all his new workers.

Training

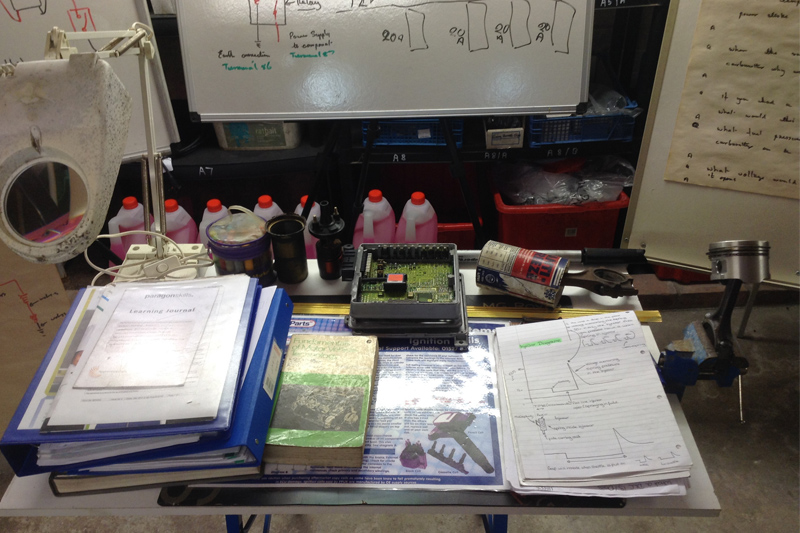

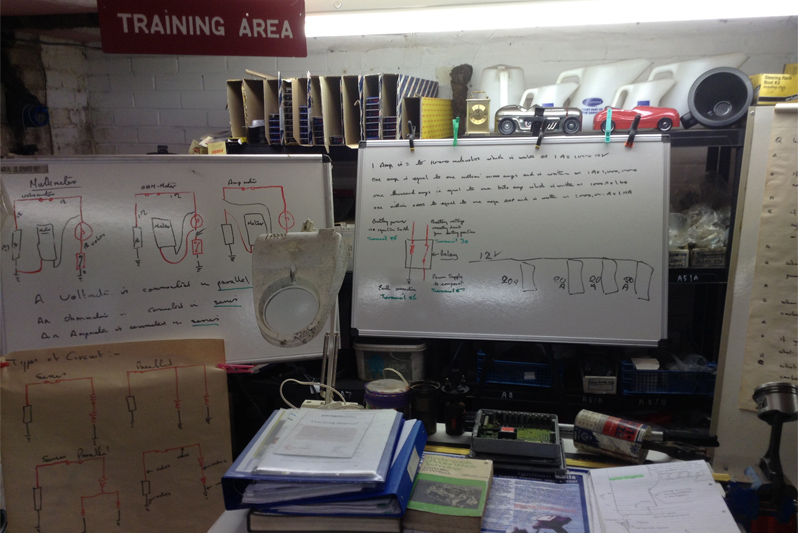

Upon walking around Dave and Mark’s workshop, it’s clear to see their passion for the industry and the importance they place on the next generation of technicians. The workshop is immaculate, everything has a place, with the addition of a training room for their apprentices (Adam and Harrie), which is solely theirs to use. There are numerous reference books, training DVDs and a selection of real car parts that have been dissected to help illustrate their inner workings, not just for their students, but for customers as well. The training room is also open after hours to the apprentices on a Sunday morning.

“It’s all voluntary; if they don’t want to do it, that’s fine,” says Dave. “You learn by your mistakes, but it’s not always about making the mistake, it’s about how you get yourself out of it. If you break a bolt off or if it is rusted up and it snaps off, you’ve got to be able to know how to drill it out, how to thread it and all that. It’s not something the training providers necessarily have time to do.

“We use the diagnostic machines to put up faults on our own cars and try and diagnose what the problem is. They’ve got all morning with no time limit to go over and over the same thing until they’ve got it. We learn how to sharpen drills, how to weld, and little things like this that you need to have in this career. That’s what Sunday mornings are all about.

“We are one of very few garages in the area to do this, and the local college can’t believe we do this for our apprentices. To see the growth and development in somebody who comes here not knowing anything, but who goes on to expand their skills and knowledge, is very rewarding”.

Dave is in regular contact with the college instructors to find out how the students are progressing. This allows time to be set aside to focus and build on any problem areas, or to support the areas the trainees are doing well in. “The quality of the college training is excellent. I went for a tour of the college myself and to meet the instructors – their facilities are fantastic. These kids have got it made. If they’ve got the enthusiasm and drive, then it’s there for the taking.”

Money and time

Time and funding seem to be two of the biggest concerns that garages have when it comes to taking on apprentices, and as a result, many don’t want to make the commitment.

On this point, Dave said: “Colleges have trouble finding placements for their students. Garages just don’t want to take on apprentices.

“We are taking the risk. The apprentices are not going to earn us anything for a couple of years, but we are prepared to take an enormous amount of time to invest in these guys, because we want to put something back into the trade. When old guys like me have given it up, there should be a steady flow coming along all the time, but I don’t think that’s going to happen at the current rate of progress.

“The other problem with training in the automotive trade is that if somebody hits their twenties and wants to become a mechanic, they can’t, because they’re too old for the apprenticeship.”

This is something that hasn’t gone unnoticed in the trade which is evident with the recent legislation on the apprenticeship levy.

The future

With the complexity of cars ever evolving, independent garages need to be looking to the future and thinking about how they are going to stay ahead of the game, not just for their own business’ sake, but also for the long-term security of the aftermarket.

“I do worry what’s going to be out there in 15 years’ time. Cars are becoming more and more complex now; they’re not just nuts and bolts anymore, they’re electronic, and we need people coming through that are able to work on these sorts of cars,” argues Dave.

With such rapid changes to the automotive landscape, and technology moving at a frightening pace, some would argue that a three-year apprenticeship isn’t quite long enough. Dave certainly feels this way, commenting: “There is so much to learn now. In my opinion, it should go back to four years. It’s not fair on the college – I’m sure the trainers are really enthusiastic about the course and I’m sure they would like to diversify, but they have to keep to the modules, otherwise they fall behind and then they’re struggling to catch up.”

“But, the college is doing a great job for these guys, and they’re doing well! There’s some good ‘uns out there, some good lads.”